Introducing our Reasearch

Principal Contents of Research

Studies of thermal engineering

For thermal efficiency improvement of an engine, we study on combustion and heat loss of the engine. Using the beam down solar concentrator, as shown in the picture, which has been constructed in the University of Miyazaki in August, 2012, we also study on a heat engine, a solar furnace and so on.

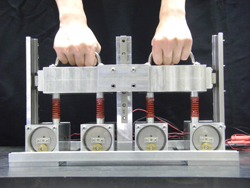

Development of handheld type power tools realizing low physical load

The frequent user of handheld type power tools, such as impact drill, tamping rammer and so on, is at high risk for developing various physical diseases known as hand-arm vibration syndrome. These diseases are caused by excessive exposure to hand-arm vibrations. The purpose of this study is to develop a new power tool using self-synchronization phenomena in order to realize low physical load.

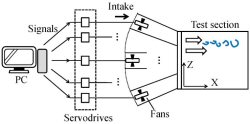

Fluid mechanics

Using a unique wind tunnel driven by multiple fans, we are searching for how to manipulate it to simulate the atmospheric turbulence. Settling scale models of vehicles or structures like a photovoltaic system in the tunnel provides information on how to prevent natural hazard.

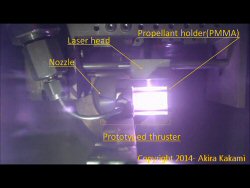

Study on microthruster (small rocket engines for spacecraft) and electric propulsion devices

A throttleable solid propellant

microthruster using laser heating.

We study microthrusters (small rocket engines) that are applicable to microsatellites. Today, universities successfully launched their self-made microsatellites into space. Nevertheless, most conventional microsatellites have no thrusters. Hence, high performance microthrusters have been attracted in order to conduct more aggressive missions.

We have proposed new microthrusters for microsatellites: liquefied gas bipropellant thrusters, throttleable solid propellant thruster using laser-assisted combustion, and electric propulsion devices. The prototypes are tested in a vacuum chamber to evaluate the performance.

Whereas evaluating thrust of microsatellite is necessary for precise missions, conventional thrust measurement device has evaluation errors in rapid thrust variation. Hence, in order to evaluate time variation in thrust in the wide frequency range, we design a new thrust measurement method that is based on a null balance method with an acceleration-based compensation. Further information is shown here.

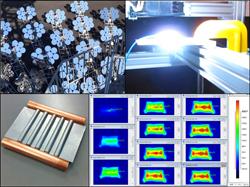

Studies on thermo-mechanics of materials and material engineering

Our research interests are technologies for effective utilization of energy and resources, improvement and preservation of the environment. Specifically, we are engaged in experiment and analysis of heat transfer and thermal stress in solar heat appliances, application of heat insulation paint to environmental improvement in summer heat and energy saving, and development of porous ceramics by recycling and reusing waste glass fiber reinforced plastics and its application.

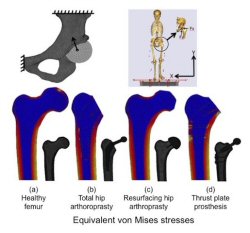

Researches on the materials and shape of the implant for artificial joints

Artificial joints are commonly used for the recovery of human motion functions. But because of the differences in the material properties between the artificial joint and human bone, osteoporosis owing to stress shielding will occur after a long period of use. This research deals with the materials and the shapes of implants, as well as the contact situations and load flow before and after the artificial joint replacement for prevention of the osteoporosis.

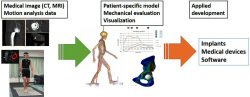

Biomechanical imaging based on the patient-specific finite element analysis

Our goal is to develop a "Biomechanical Imaging based on the Patient-specific Model" system (simulation technique). The system can evaluate and visualize mechanical environments of musculoskeletal system (bone, joint, cartilage, and muscles) under daily living activities, in the end, can predict the mechanical state of the future. Using this system, we are now developing innovative medical devices (implants, devices, software) by interdisciplinary research based on the industry-government-academia.

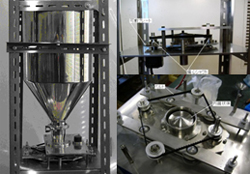

Utilization of mechanical vibration

In the mechanical system, the vibration phenomenon have to be avoided. On the contrary, our laboratory is executing the research on effective utilization of mechanical vibration. The machines developing in our laboratory are a vibration-type mixer and a powder feeder (powder feeding device), etc. The photos show a high-performance cone-typed powder feeder. This novel powder feeder is capable of stably, continuously supplying a fixed quantity of powder per unit time with high accuracy in spite of a simple mechanism is adopted.

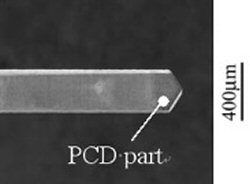

Study on precision and micro machining

We mainly deal with research in the field of precision and micro machining. In this field, we have studied development of micro tools and establishment of their manufacturing methods for the purpose of realizing high-precision and high-efficient machining. Furthermore, we have studied machining technique and applications by using these developed tools.

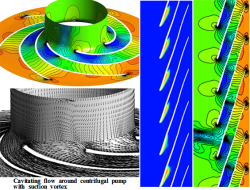

Research on engineering application of fluid mechanics

This lab conducts studies on developing numerical schemes and computational programs to clarify the complex flow phenomena and their general rules of compressible, incompressible, viscous and multi-phase flow, and research on engineering applications of flow physics for optimal design and flow control of fluid devices.